Who is USA Made Factory?

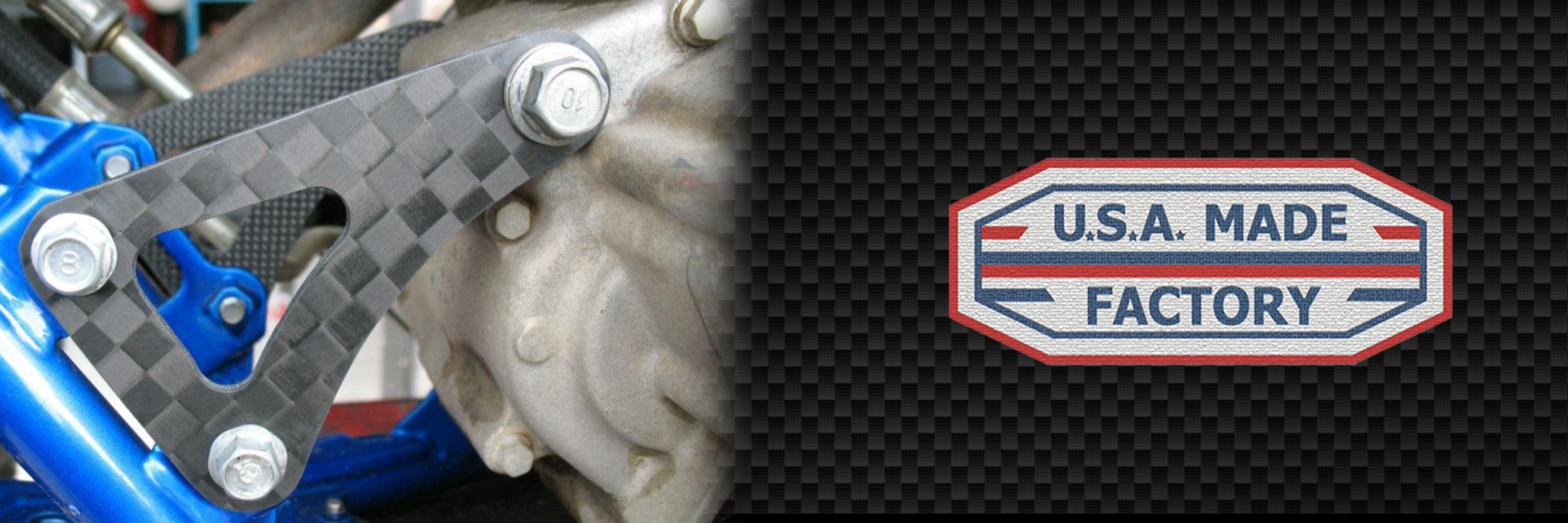

USA Made Factory is an engineering and design firm for composites and composite parts. We design and manufacture for multiple industries in our expansive facilities right here in Woodland, Washington USA. We produce and manufacture outdoor products for fishing rod blanks, boat oars, net handles and much more. From suspension rods to drone arms - Carbon fiber brackets to parts that take rockets to space. USA Made Factory is continuing to push the envelope for design with composites. We believes that no idea is too small. We are firm believers that an idea can turn into more than just a thought and will help you put your idea into motion. Our goal is to provide you with the highest quality product that is effective, cost efficient and above all is exactly what you need to get your job done.

LEADERSHIP

There are leaders, and then there's everyone else. At USA Made Factory, we take immense pride in driving the industry standards forward and focusing on efficiency, quality, and innovation. Our team drives it all home. We give it our all, never give up and we are not afraid to try new ideas! We believe in American made products!

QUALITY

Our standards are your standards, with the highest quality of craftsmanship. No one ever complained about having their work executed perfectly. We know that some of your products might need us to offshore a few pieces. We see the big picture.

TECHNOLOGY

We produce our products on U.S. soil on machines that are made in the USA. Our machines and processes are the most technologically advanced. We take pride in our partnerships across the globe. Our network is full of innovative leaders that strive for the best.

CONSULTING

Our team has over 70 years combined experience in the composite industry. We're the official training facility for Century Design. If you are interested in developing a new product, or ready to start your own factory, we can help you reach your goals. Our Tips for Tubes program will guide you through the manufacturing process.

OUTDOORS

We have a passion for the outdoors as well as to create new products for the outdoor industry. We build and supply OEM products for the outdoor industry distribution. USA Made Factory is constantly pushing the envelope for component designs for outdoor distributors like Talon Rods.

Equipment Capacity at USA Made Factory

We operate multiple CDI machines, along with a variety of other advanced equipment, capable of producing a wide range of carbon fiber and fiberglass tubes — from diameters .030 up to 12" and as short as you need up to 10'6" long. Our experienced team not only runs this machinery but also maintains it in top operating condition to ensure consistent, high-quality results. Depending on the part requirements, we can tailor our process to deliver the ideal solution for your application. Whatever the size or complexity, we have the equipment and expertise to get it done right. Below is a list of our machinery and the production capabilities at USA Made Factory.

CDI Auto Shear

Qty: 2

The CDI Auto Shear is built for fast, precise cutting of carbon fiber materials up to 50" wide. Designed for production efficiency, it delivers clean, accurate cuts with consistent repeatability across a wide range of layups and thicknesses. The automated feed and shear system reduces handling, improves edge quality, and ensures every piece is prepared to exact dimensions. Ideal for high-volume composite part manufacturing, the CDI Auto Shear streamlines prep work while maintaining the reliability and accuracy demanded in advanced materials processing.

CDI Auto Slit/Shear

Qty: 1

Our CDI Auto Slit/Shear machine provides fast, accurate cutting and slitting of carbon fiber materials up to 50" wide. Designed for precision composite prep, it combines automated feeding, slitting, and shearing in one efficient system—producing clean edges, consistent widths, and highly repeatable results. Whether you’re creating narrow slit tape or full-width cut sheets, the machine delivers tight dimensional control and smooth workflow integration. Ideal for both high-volume production and specialized part programs, the CDI Auto Slit/Shear ensures your material is prepared exactly to spec every time.

CDI Rolling Table

Qty: 6

Our CDI Rolling Table is engineered for precise, consistent layup of carbon fiber tubes. Designed to support the filament-winding or roll-wrapping process, it provides a stable, smooth rolling platform that ensures even material tension and accurate fiber placement. The adjustable rollers accommodate various mandrel sizes, maintaining alignment and helping produce tubes with uniform wall thickness and clean, repeatable layups. Durable and operator-friendly, the CDI Rolling Table streamlines tube production and enhances overall quality in composite manufacturing.

CDI Cellophane Wrapper

Qty: 6

Our CDI Cellophane Wrapper is designed to tightly and uniformly wrap carbon fiber tubes during the curing or consolidation process. By applying controlled tension, the system compresses the laminate, removes excess resin, and helps achieve smooth, consistent surface finishes. The adjustable feed and wrap settings accommodate a wide range of tube diameters, ensuring clean, repeatable results across all production runs. Reliable, efficient, and easy to operate, the CDI Cellophane Wrapper is an essential tool for producing high-quality carbon fiber tubes with precision.

CDI Manual Shear

Qty: 1

Our CDI Manual Shear is a dependable, easy-to-operate cutting solution for carbon fiber and composite materials. Designed for accuracy and control, it delivers clean, straight cuts without fraying or fiber pull. The sturdy frame and sharpened shear blades ensure smooth operation, while the manual design gives operators full control over each cut—ideal for smaller batches, prototyping, and quick material prep. Durable, precise, and simple to maintain, the CDI Manual Shear is a proven shop-floor tool for preparing composite materials to exact specifications.

CDI Centerless Wet Sander

Qty: 3

Our CDI centerless wet sander delivers precise, uniform finishing for carbon fiber tubes and composite components. Its continuous wet sanding process reduces heat and dust while ensuring consistent 360-degree material removal and tight OD tolerances. With adjustable feed control and multi-grit capability, it handles a wide range of diameters and finish requirements. Durable, efficient, and easy to operate, it produces clean, repeatable surface quality for any production run.

Curring Oven

Qty: 5

Our curing oven is purpose-built for baking and post-curing carbon fiber parts with precise, uniform temperature control. Engineered for composite manufacturing, it delivers consistent heat distribution to ensure proper resin cure, optimal strength, and stable part geometry. The insulated chamber, programmable controls, and reliable airflow system maintain tight thermal tolerances throughout each cycle, reducing defects and improving overall part quality. Designed for durability and efficiency, this curing oven provides dependable performance for everything from small components to large carbon fiber assemblies.

Mandrel Extractor

Qty: 3

Our CDI centerless wet sander delivers precise, uniform finishing for carbon fiber tubes and composite components. Its continuous wet sanding process reduces heat and dust while ensuring consistent 360-degree material removal and tight OD tolerances. With adjustable feed control and multi-grit capability, it handles a wide range of diameters and finish requirements. Durable, efficient, and easy to operate, it produces clean, repeatable surface quality for any production run.

Mandrel Warming Table

Qty: 8

Our mandrel puller is engineered to safely and efficiently extract mandrels from cured carbon fiber tubes and composite parts. Built for consistent pulling force and smooth operation, it helps prevent fiber distortion, surface damage, or unwanted stress during de-tooling. The adjustable clamping system accommodates a wide range of mandrel sizes, while the controlled pull action ensures clean, repeatable results across all production runs. Durable, reliable, and operator-friendly, the mandrel puller streamlines post-cure processing and keeps your workflow moving efficiently.